2020年06月11日Dynamikwell-Flexible intelligent manufacturing pulsating production line

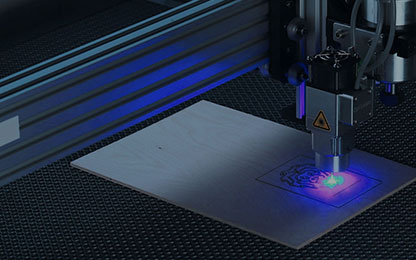

Shenzhen dynamikwell technology co., LTD. is a Sino-foreign joint venture high-tech enterprise and a professional manufacturer of direct drive motors and automation equipment that is in line with international standards. The company introduces foreign advanced manufacturing technology and testing methods, adopts high-tech equipment and high-quality materials, develops and produces high-end linear motors, precision direct-drive motion platforms, precision controls and drives and other high-tech products, which are widely used in precision CNC machine tools and precision laser cutting. Systems, electronics and semiconductor equipment, high-end medical equipment and other fields.

Dynamikwell is strong in research and development, bringing together high-tech talents at home and abroad. The management team is composed of technical experts and professionals with modern management experience. The human resource structure is complementary to form a scientific management and operation mechanism. Dekangweier always maintains the pursuit of product performance, precision, accuracy and speed, and constantly innovates, and strives hard to realize the historical mission of improving the level of China's equipment manufacturing equipment.

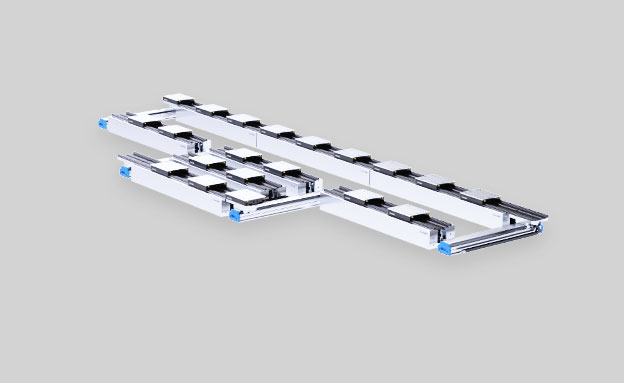

Based on independent R&D and production, Dynamikwell launched a flexible manufacturing intelligent pulsating production line. The production line has 10 advantages such as three-dimensional conveying, infinite loop, flexible manufacturing, arbitrary combination, man-machine mixing, precision and efficiency, intelligent application, high cost performance, module production, and simple debugging.

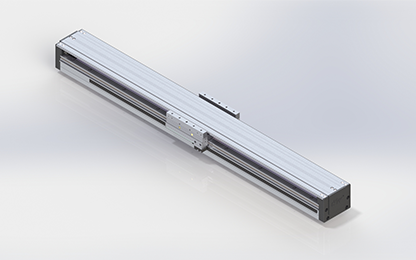

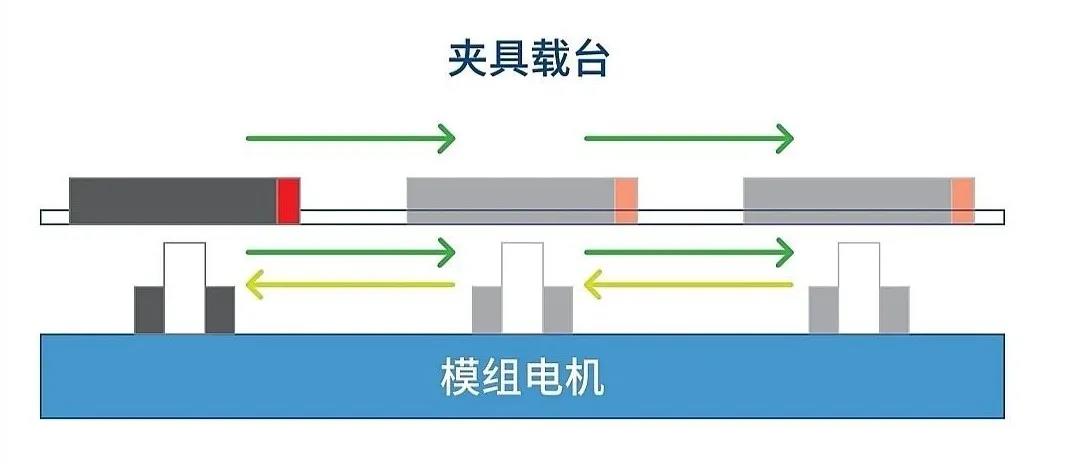

The pulsating production line uses the characteristics of linear motor multi-movers to realize the function of "relay transmission". Push the fixture stage forward step by step. The motor only needs to reciprocate between two points to achieve precise positioning of the work position. After in place, the fixture carrier is fixed by the locking device.

The corner connection uses the guide rail dynamic splicing method to transport the fixture carrier (with slider) to the connection device. After receiving the instruction, the connection device takes the fixture carrier to the next connection point to splice the guide rails. The linear motor has a repeat accuracy of 5μm, which greatly reduces the splicing error.

Rotary connection method, using high-precision DDR as the steering conductor, 360 ° change the direction of the connection method, greatly improving the scalability of the production line.

The upper and lower connection method independently developed by Dynamikwell is suitable for the production line structure with high space requirements. The lower transmission mechanism can be an ordinary single-axis standard module. The modular upper and lower connection module: MDC1511.

The control method of the pulse production line has the following characteristics:

(1)The topology is simple:A master station can control 255 slave motors, and the control cable is a network cable

(2)High response:The synchronization cycle is less than 1ms, the instruction cycle time is shorter, and the synchronization coordination is higher.

(3)Diagnosis:Through real-time monitoring of the working status of all motors and their components in the loop.

(4)Easy to maintain:Through the network cable interface, it is convenient to increase the control axis and adapt to other master station controllers.

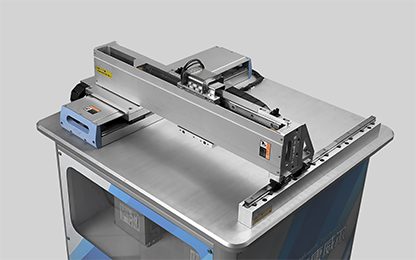

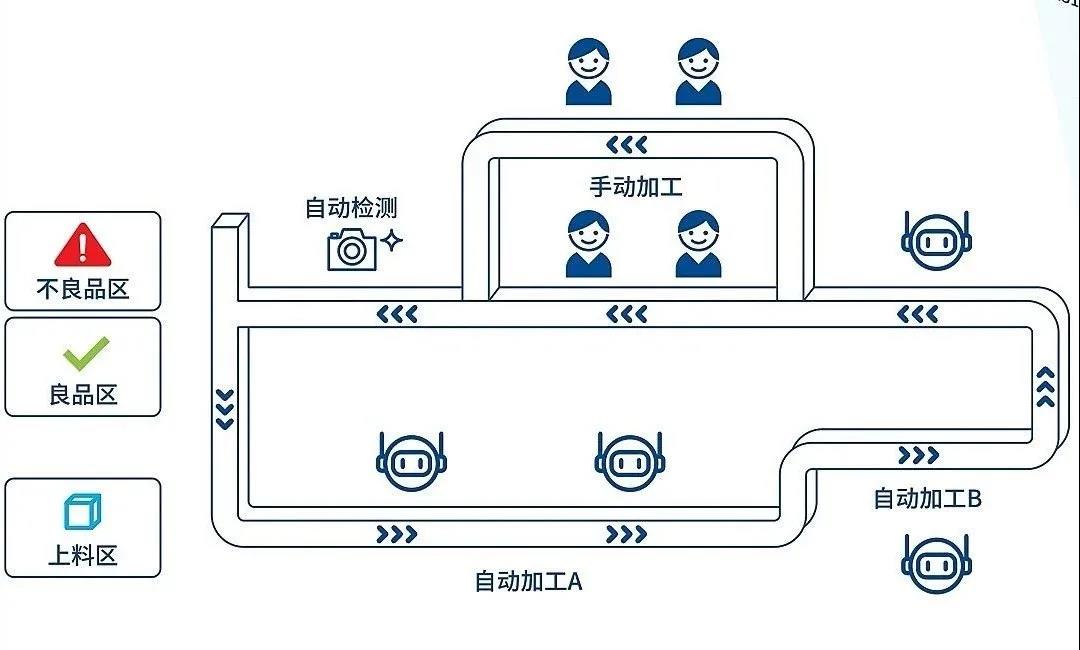

Manual inspection and machine production are carried out simultaneously

●Technical Parameters of Pulse Production Line

●Automatic/manual compound pulsating production line

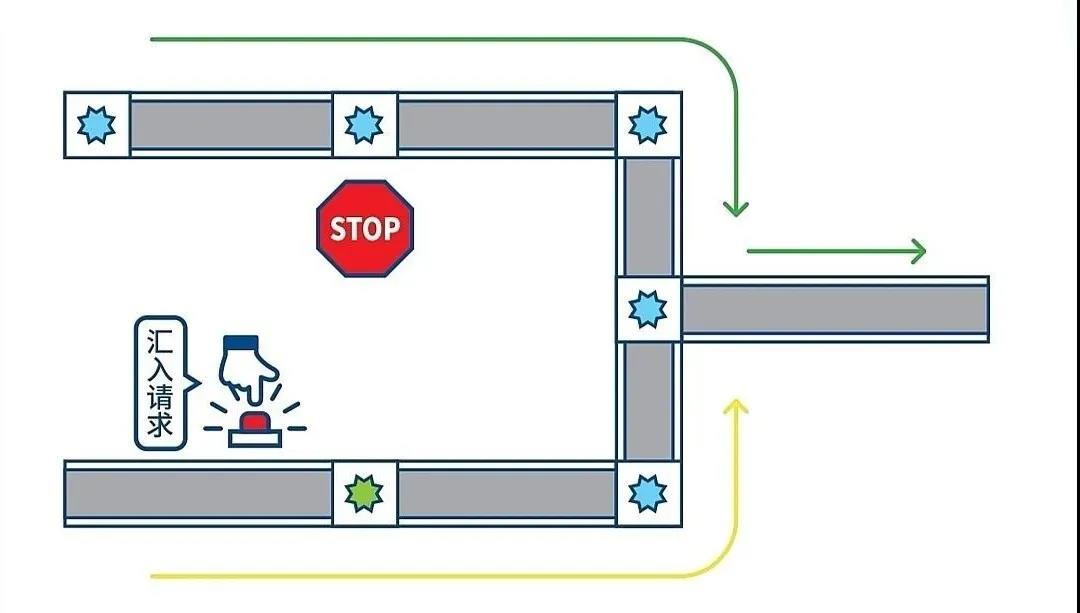

●Confluence operation of pulsating production line

Set multiple entrances and one exit at the connection point to realize the confluence function. For example, manual re-inspection of the production line, through the import request button, the re-inspection OK products are merged into the normal circulation production line.

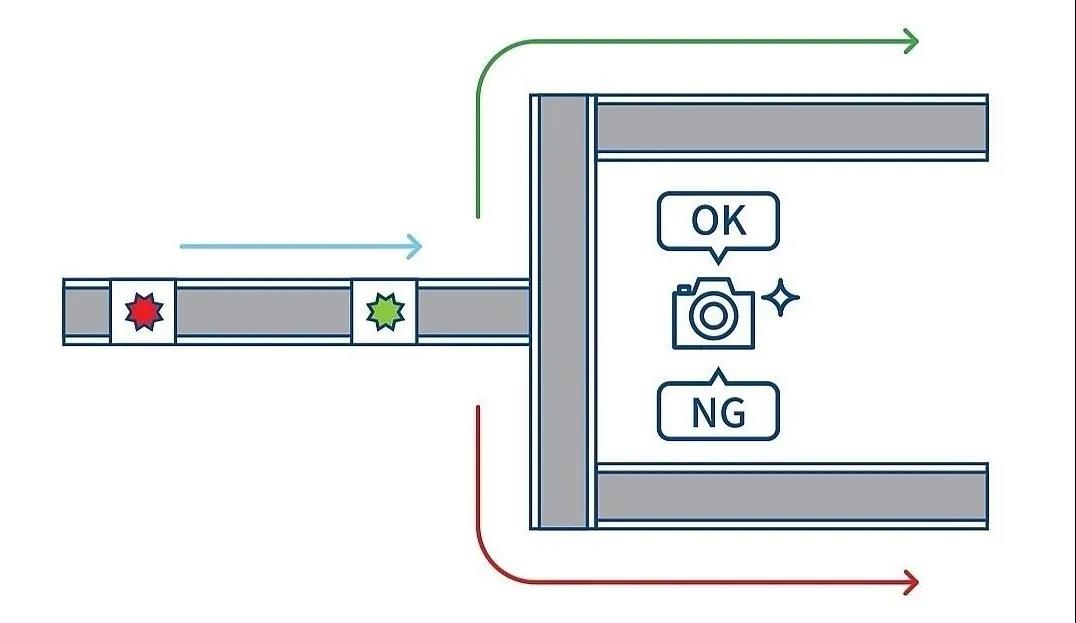

●Diversion operation of pulsating production line

Design an inspection and judgment station at the connection entrance, and set up two connection outlets to realize the diversion function, for example, the production line products are tested, and the OK products and NG products are flowed into different production lines.

●The pulse production line has the following advantages:

Higher accuracy:The closed-loop feedback device with a resolution of up to 1μm can achieve a repeatability of less than 5μm.

Wireless loop:The output of the motor energy drives the station transfer of the fixture carrier, which can realize the periodic cycle of the production line.

Higher speed:With a load of up to 50kg, the maximum speed of 2.5m/s can also be easily achieved, and the efficiency of the production line is greatly improved.

Flexible topology:Complicated diversion and confluence conditions can be easily solved with flexible and diverse connections.

The pulse production line can be widely used in medical production, smart logistics, packaging and printing industry, semiconductor industry, photovoltaic industry, food packaging industry, lithium battery industry, and 3C industry.